Porduks

Kita nyedhiyakake macem-macem solusi kanggo kabutuhan, apa sampeyan mbutuhake bahan standar utawa desain khusus.G80 rantai ireng g80 kanggo ngangkat

Katrangan

Rantai angkat minangka piranti sing digunakake kanggo ngangkat lan ngangkut obyek sing abot, biasane kalebu pirang-pirang tautan logam. Link iki bisa digawe saka baja, aloi utawa bahan liyane kanggo nahan bobot lan tekanan obyek abot. Rantai angkat umume digunakake ing peralatan mekanik kayata Cranes, Cranes, lan Elektor kanggo nyedhiyakake dhukungan stabil lan rantai transportasi minangka piranti pick-up penting lan penting kanggo kren. Dawane chain bisa diatur miturut dhuwur saka obyek angkat.

Lumahing rantai chain: polishing, blackening, cat cat, gantung plastik, electroplating.

Standar Pabrik Chain Angkat: iso1077, en818-2, as2321.

Jurujamin slamet chain: 4 kaping faktor safety, 4 kaping beban tes.

Katrangan rinci

1. Pilih Bahan: Kekuwatan dhuwur lan sregep kanthi kuat kanthi stabilitas;

2 .. Desain Struktur Sederhana: Gampang digunakake, gampang diganti, ngirit tenaga kerja;

3 .. Perawatan permukaan produk: Lumahing wis polesan, dicet lan proses multi-lapisan liyane kanggo nglindhungi produk kasebut;

4 Kinerja .Stable: Sawise pangolahan bathi bola-bali, produk kasebut duwe bathi sing akeh lan ora gampang dibuang;

Tampilan Detail

Paramèter

| Zize DXP (MM) | Jembaré | Kira-kira bobot (kg / m) | MOLYIMIT (T) | Tes beban (K KN) | Breadload Min.kn | |

| Ing njero min.w1 | Njaba max.w3 | |||||

| 3 × 9 | 3.8 | 10.7 | 0,21 | 0,28 | 7.1 | 11.3 |

| 4 × 12 | 5 | 14.3 | 0.35 | 0,5 | 12.6 | 20.1 |

| 5 × 15 | 6.3 | 17.9 | 0.54 | 0,8 | 19.6 | 31.4 |

| 6 × 18 | 7,5 | 21 | 0,79 | 1.1 | 27 | 4.2 |

| 6.3 × 19 | 7.9 | 22.6 | 0.86 | 1.25 | 31.2 | 49.9 |

| 7 × 21 | 9 | 24.5 | 1.07 | 1.5 | 37 | 61.6 |

| 8 × 24 | 10 | 28 | 1.38 | 2 | 48 | 80.4 |

| 9 × 27 | 11.3 | 32.2 | 1.76 | 2,5 | 63.6 | 102 |

| 10 × 30 | 12.5 | 35 | 2.2 | 3.2 | 76 | 125 |

| 11.2 × 33.6 | 14 | 40.1 | 2.71 | 4 | 98.5 | 158 |

| 11 × 43 | 12.6 | 36,5 | 2.33 | 3.8 | 92 | 154 |

| 12 × 36 | 15 | 42 | 3.1 | 4.6 | 109 | 181 |

| 12.5 × 38 | 15.5 | 42.2 | 3.3 | 4.9 | 117 | 196 |

| 13 × 39 | 16.3 | 46 | 3.8 | 5 | 128 | 214 |

| 14 × 42 | 18 | 49 | 4.13 | 6.3 | 150 | 250 |

| 14 × 50 | 17 | 48 | 4 | 6.3 | 150 | 250 |

| 15 × 46 | 20 | 52 | 5.17 | 7 | 168 | 280 |

| 16 × 48 48 | 20 | 56 | 5.63 | 8 | 192 | 320 |

| 16 × 49 | 24.5 | 59.5 | 5.71 | 8 | 192 | 320 |

| 16 × 64 | 23.9 | 58.9 | 5.11 | 8 | 192 | 320 |

| 18 × 54 | 23 | 63 | 6.85 | 10 | 246 | 410 |

| 18 × 54 | 21 | 60 | 6.6 | 10 | 246 | 410 |

| 19 × 57 | 23.7 | 63.2 | 7.7 | 11.3 | 270 | 450 |

| 20 × 60 | 25 | 70 | 8.6 | 12.5 | 300 | 500 |

| 22 × 65 | 28 | 74.2 | 10.7 | 15.3 | 366 | 610 |

| 22 × 66 | 28 | 77 | 10.2 | 15.3 | 366 | 610 |

| 22 × 86 | 26 | 74 | 9.5 | 15.3 | 366 | 610 |

| 24 × 72 | 32 | 82 | 12,78 | 18 | 432 | 720 |

| 24 × 86 | 28 | 79 | 11.6 | 18 | 432 | 720 |

| 26 × 78 | 35 | 91 | 14.87 | 21.3 | 510 | 720 |

| 26 × 92 | 30 | 86 | 13.7 | 21.3 | 510 | 850 |

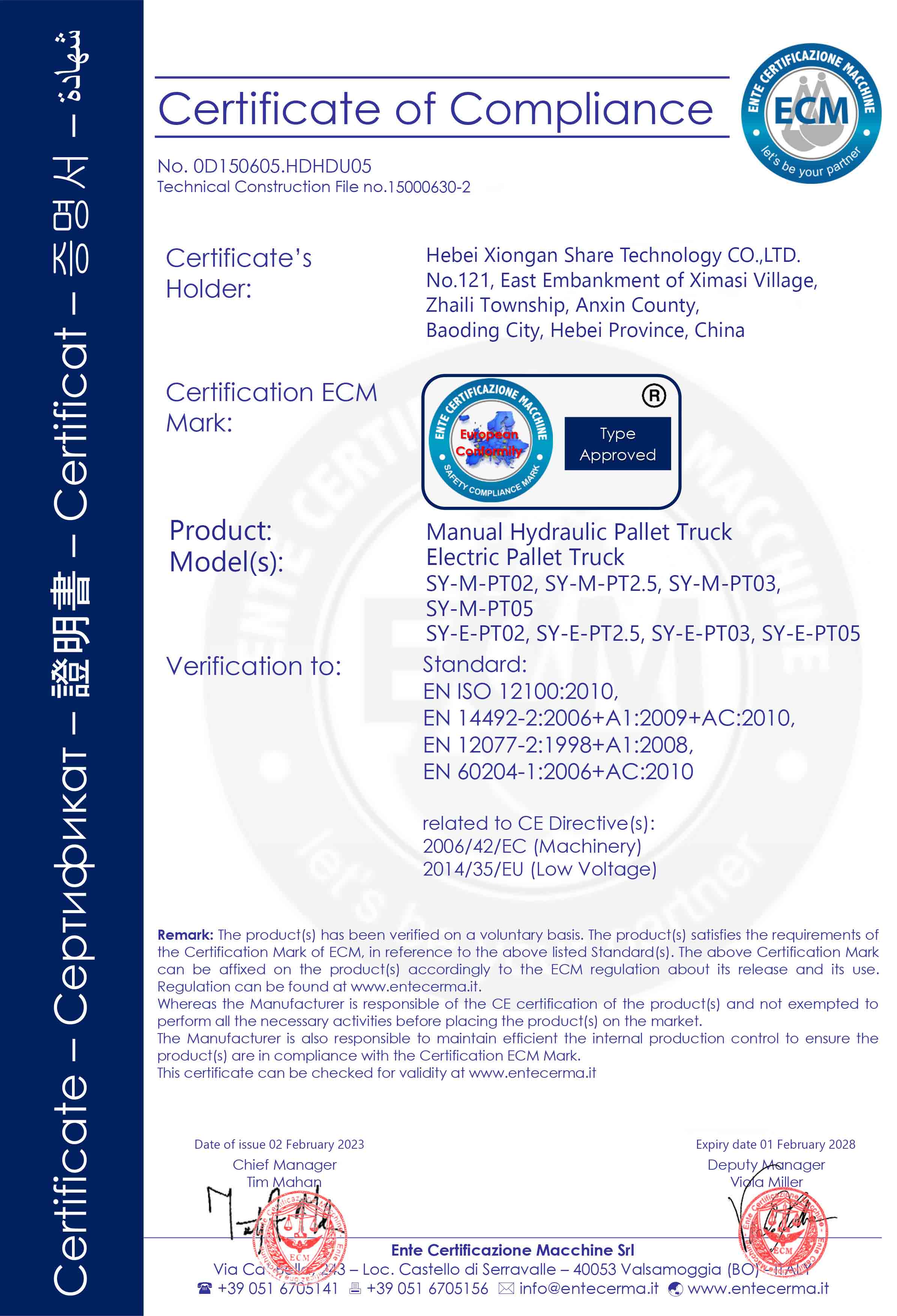

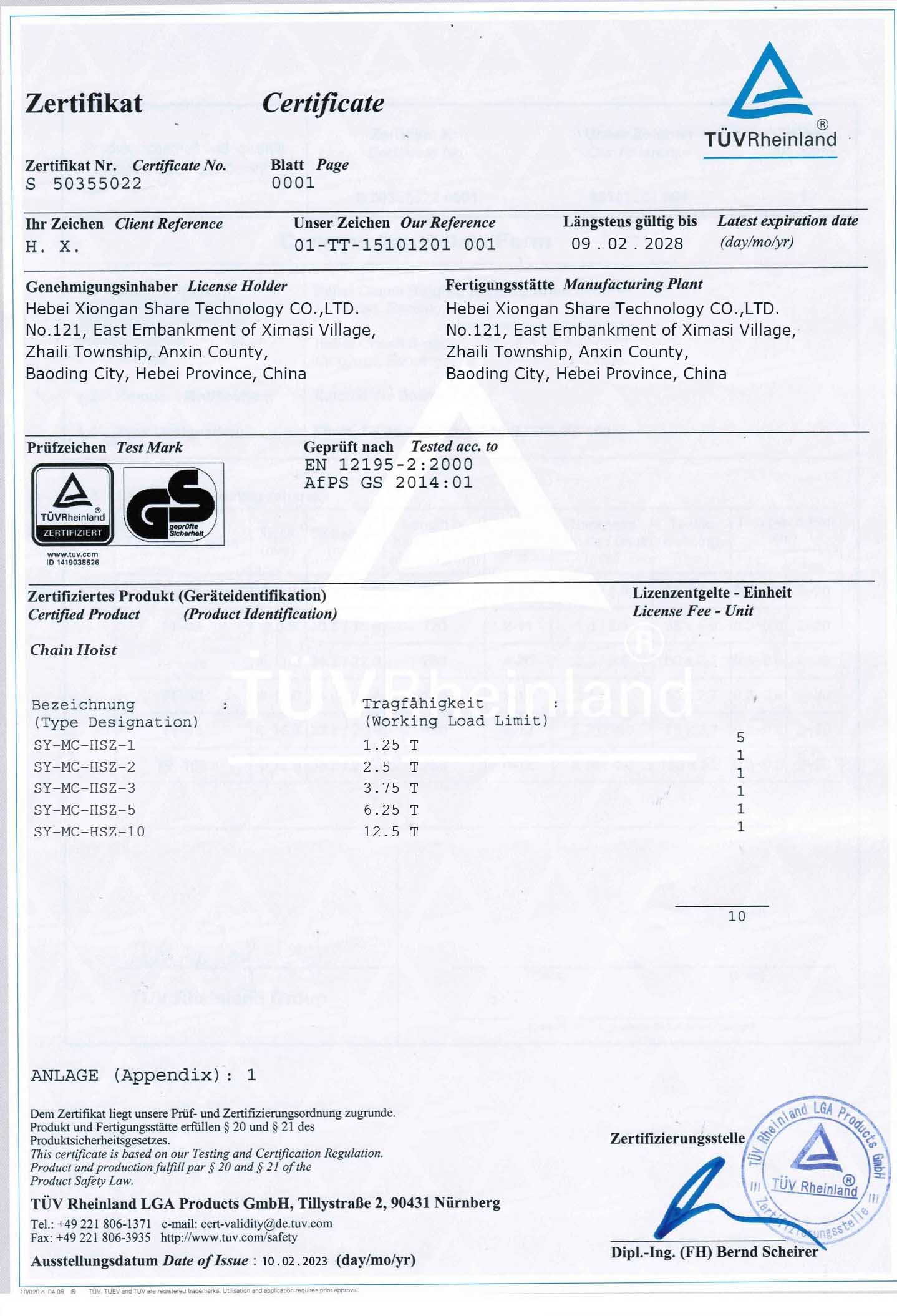

Sertifikasi kita